The motor industry has experienced a silent revolution that has been costly in the past ten years. The range of battery and horsepower is the priority of the consumers, but the structural and technological complexity of the exterior parts of the vehicle has grown exponentially. There is no place where this is more visible than in the front windshield.

A plain sheet of laminated glass has now been transformed into a complex optical lens, which forms the main eyes of the vehicle, the Advanced Driver Assistance Systems (ADAS). This has resulted in a change in the economic calculus of safeguarding this asset. This paper gives a strict discussion of windshield protection, the physics of the materials, the economics of protection films and insurance, and the manufacturing technologies that make the difference between the premium protection and the temporary stopgaps.

Why Modern Windshields Are So Expensive to Replace

In order to comprehend the value proposition of windshield protection, it is necessary to first deconstruct the replacement cost structure. In the past, a broken windshield was a small inconvenience, which was fixed at a local glass shop at a few hundred dollars. The same crack is a huge financial liability today.

The driver is not just paying to be recalibrated; they are paying to have a complicated sensor suite recalibrated. Cameras, LiDAR and rain sensors are built into the windshield assembly of modern vehicles. These features control autonomous emergency braking, lane-keeping assist, and adaptive cruise control. These sensors are physically disturbed when a windshield is changed.

The replacement process has now two different costs:

- The OEM Glass: Luxury and electric car manufacturers usually use special acoustic or infrared-reflective glass, which may cost between 800 and more than 2000 dollars.

- ADAS Recalibration: This is the latent multiplier. Special technicians and equipment are needed to perform the recalibration, which is usually an extra charge of $500 to 1000 to the bill.

Moreover, it can be depreciated through repair. Aftermarket glass might not be of the exact optical clarity needed by OEM sensors, and this can result in system faults. Therefore, the fact that the original factory-installed glass (OEM) is preserved is no longer merely a matter of aesthetics; it is a matter of the functional integrity of the safety systems of the vehicle.

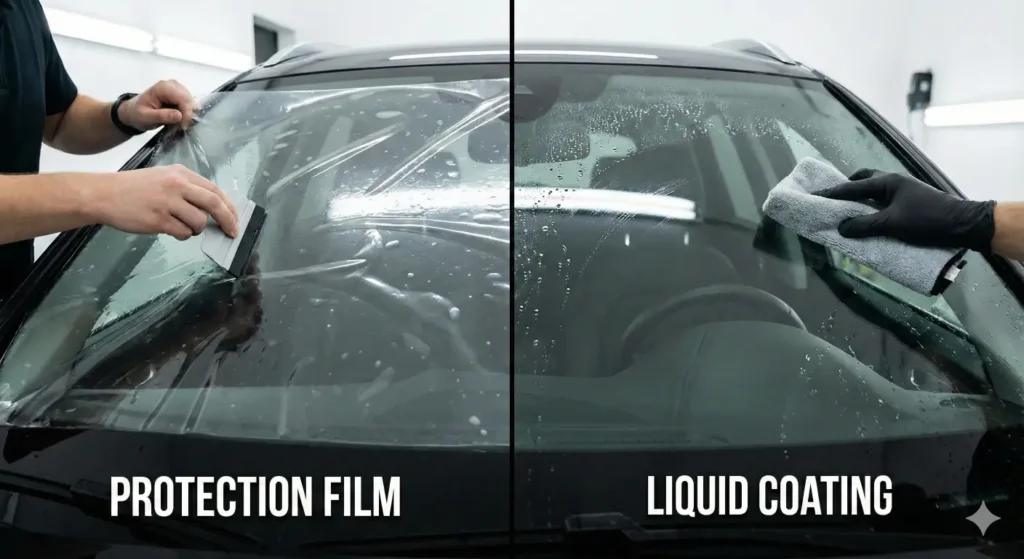

Mainstream Solutions Compared: Protection Film vs. Liquid Coating vs. Glass Insurance

When a vehicle owner seeks to mitigate the risk of damage, the market offers three distinct mechanisms. It is crucial to distinguish between chemical treatments, financial hedging, and physical barriers.

To clarify the functional differences between these approaches, we can analyze them across key economic and operational metrics:

| Feature / Metric | Liquid Coating (Nano) | Glass Insurance | Windshield Protection Film |

| Primary Mechanism | Chemical Hydrophobicity | Financial Risk Transfer | Physical Kinetic Absorption |

| Impact Protection | None. Cannot stop rock chips. | Reactive. Fixes damage after it happens. | Proactive. Prevents damage before it occurs. |

| OEM Seal Integrity | Maintained | Lost. Replacement breaks factory seal. | Maintained |

| Time Cost | Low (15 min application) | High (Days/Weeks for parts & calibration) | Moderate (2-3 hour installation) |

| Cost Structure | Low ($20 – $50) | Monthly Premium + Deductible | One-time Investment ($300 – $600) |

| Lifespan | 3 – 6 Months | Annual Renewal | 1 – 3 Years (Dependent on maintenance) |

| Best For | Improving rain visibility | Drivers who don’t mind downtime | Luxury/EV/Off-road owners |

Liquid Coating (Nano/Ceramic Treatments)

Liquid glass products are based on nanotechnology to fill microscopic pores on the surface of the glass.

- The Mechanism: These coatings form a hydrophobic surface, which causes water to bead and roll off, which enhances visibility during precipitation. They also assert that they make the glass a little harder on the surface (measured using Mohs scale).

- The Verdict: Liquid coatings are effective in terms of visibility and easy cleaning, but they provide insignificant protection against kinetic energy. A 5mm diameter stone moving at 70 mph has sufficient momentum to break through the hydrophobic layer and crack the glass substrate below. It is a visibility solution, rather than a protection solution.

Glass Insurance (Financial Hedging)

It is not a preventative measure but a risk-transfer mechanism.

- The Mechanism: The owner pays a premium to an insurer who will cover the replacement cost, and usually with a deductible.

- The Verdict: Insurance covers the financial shock but does not cover the downtime of the operation. A vehicle can sit on its wheels weeks before claim approval, parts ordering (OEM glass is often backordered) and calibration appointments. Moreover, claims made repeatedly may cause a rise in premiums. Most importantly, insurance fails to maintain the factory seal of the windshield installation which is better than any aftermarket bond.

Physical Barrier (Protection Film)

Windshield Protection Film (WPF) is a polyester laminate that is a multi-layer and is placed over the exterior of the glass.

- The Mechanism: It is a sacrificial layer. When an object collides with the windshield, the film will absorb the impact energy and spread it laterally across the surface area of the film, eliminating the localized stress spike that causes glass to chip or crack.

- The Verdict: This is the sole remedy that will deal with the cause of the problem: the impact itself. It is successful in transforming a disastrous structural failure into a trifling cosmetic blemish on a substitutable film.

Technical Deep Dive: How Windshield Protection Film Actually Works

To evaluate the efficacy of a protection film, we must look beyond the marketing and into the materials science. Not all clear films are created equal; the specific engineering requirements for a windshield differ vastly from those for paint protection.

The Material Battle: Why PET Outperforms TPU on Glass

It is a widespread myth that Windshield Protection Film is just Paint Protection Film (PPF) on glass. This is incorrect. PPF is commonly made of Thermoplastic Polyurethane (TPU), a soft elastomeric substance that is self-healing.

Nevertheless, TPU cannot be used in windshields due to one important factor friction. TPU is very coarse and its texture is rubbery. When used on a windshield, the windshield wipers would drag, chatter and ultimately bind damaging the wiper motor and the film.

Polyethylene Terephthalate (PET) is used in windshield films. PET is a thermoplastic polymer resin which is highly stiff, has a high level of dimensional stability and most importantly, high optical clarity. PET has a molecular structure that enables it to be produced as a rigid, glass-like surface that can be glided over by wipers without any difficulties. The problem of engineering is to overlay this hard PET in a manner that is flexible enough to fit around the compound curves of the current windshields without bending the vision of the driver.

The Physics of Impact Resistance: Scattering the Force

Glass is weak because it cannot deform plastically; it is brittle. When a rock hits a windshield, it provides a high point load, which is an extreme amount of force focused on a minute spot. This concentration of stress is greater than the tensile strength of the glass and it fractures.

Windshield protection film works by dispersion of force. The movie has some elasticity and tensile strength which is not available in glass. When struck, the film folds and unfolds a little. This deformation prolongs the impact (milliseconds) and the area of force application. The pressure on the glass below is greatly decreased by distributing the energy of a sharp rock over a larger area (e.g. 5mm 2 rather than 0.1mm 2) and in many cases this pressure remains below the fracture threshold.

The Honest Truth: Common Issues with Windshield Films

In the interest of a balanced economic analysis, one must acknowledge the depreciation curve and operational limitations of windshield films. Unlike the glass it protects, the film is not permanent.

Wiper Abrasion and Coating Degradation

Windshield film is most adversely affected by the windshield wipers rather than the debris. Over time, dust and grit between the wiper blade and the film are an abrasive compound. Despite the hard-coat layers in the modern films, the constant friction, which is thousands of cycles in each rainstorm, will eventually result in the hydrophobic top coating being worn away. This can lead to micro-marring whereby small scratches create a haze that is visible in the direct sunlight or on-coming headlights.

Low-angle Haze and Visual Distortion

The most important thing to optical clarity is safety. Orange peel textures or refraction errors can be caused by poor quality films or films that have been overstretched. This leads to visual distortion where straight lines are wavy. In addition, the adhesive layer can sometimes degrade when the PET material is aged and when it is exposed to UV radiation, and can manifest itself as a milky haze known as low-angle haze, particularly when driving into the sun.

A Manufacturer Viewpoint: The Short Lifespan Problem Solution

The above limitations, which are abrasion, optical distortion, and adhesive failure, are not impossible; they are engineering problems. In FlexiPPF, we do not just see these challenges as a vendor, but as a source manufacturer with industrial grade precision to increase the lifecycle of the film.

Through managing the whole production chain, including the choice of raw materials, extrusion and coating, we have come up with solutions that address the historical flaws of windshield films in particular.

International Material Procurement (BASF Base and Ashland Adhesive)

The duration of a movie is determined by its premise. Local substrates that are yellowed by UV light are commonly used in standard generic films. FlexiPPF uses a BASF Polyester Base that is of German origin. The chemical engineering of BASF offers a PET structure that has a high tensile strength and optical stability so that the film does not break or lose its color after some time.

Moreover, we use Ashland Adhesive of the USA to counter the problem of bubbling or adhesive breakdown in high-heat conditions (a frequent failure mode in conventional films). This adhesive offers good bonding performance, low VOC emissions and good heat resistance. It makes the film optically clear and well bonded even when the temperature of the glass increases to a high level of up to 80℃.

Precision Manufacturing with German Technology

To solve the issues of visual distortion and “orange peel,” precision in the manufacturing process is non-negotiable. FlexiPPF production lines are equipped with German Brückner polyester film production lines and advanced SLOT DIE coating equipment.

This high-precision machinery allows for a uniform application of our proprietary Nano Ceramic Coating. This is not a simple surface spray; it is an integrated layer that delivers two critical performance metrics:

- Glare Reduction: Our engineering reduces glare by up to 55%. This significantly improves driver safety during sunrise, sunset, or night driving, addressing the visual comfort concerns often cited with lesser films.

- UV Protection: The ceramic layer blocks over 99% of harmful UV rays (UV400). This goes beyond protecting the driver; it protects the dashboard and leather interior from fading, preserving the vehicle’s residual value.

Our confidence in this manufacturing process is reflected in our 10-year warranty, a standard that far exceeds the industry average for windshield protection products.

Perfect Fitment via Pre-Cutting Service

Installation error is a primary cause of film failure and visual distortion. Stretching a flat film over a curved glass surface induces stress in the material. FlexiPPF mitigates this through Precise Pre-Cutting.

We maintain a database of accurate templates for thousands of vehicle models. By pre-cutting the film to the exact dimensions of the specific make and model, we eliminate the need for installers to cut on the glass (risking damage to the seals or paint) and reduce the need for excessive heat-shrinking. This ensures the PET material retains its structural integrity and optical clarity from the moment it is applied.

The ROI Calculator: When Does Protection Film Save You Money?

Is the investment in high-quality protection film rationally justified? We can determine this through a simple Return on Investment (ROI) analysis.

The Variables:

- C (Cost of Protection): Average cost of high-quality film installation ($300 – $600).

- L (Loss Potential): Cost of OEM Windshield + ADAS Calibration ($1,500 – $3,000+).

- R (Risk Factor): The probability of damage (influenced by driving habits and vehicle design).

Scenario A: The Urban Commuter (Low Risk)

For a standard sedan driven mostly in city traffic, the risk of high-velocity stone impact is low. The replacement cost might be only $500 (no ADAS). Here, spending $400 on film yields a neutral or negative ROI.

Scenario B: The Luxury/EV Owner (High Loss Potential)

A Tesla Model X or a Porsche 911 has a massive, complex windshield. Replacement costs often exceed $2,500. Even with moderate driving, a single rock chip represents a catastrophic loss of value. Here, the film functions as an asset protection strategy. Spending $500 to protect a $2,500 asset yields a clear positive ROI.

Scenario C: The Off-Road/Highway Warrior (High Risk Factor)

Vehicles like the Jeep Wrangler or Ford Bronco feature vertical windshields that catch stones rather than deflecting them. Owners of these vehicles report replacing windshields annually. In this high-frequency damage scenario, the film pays for itself within the first year by preventing multiple replacements and the associated downtime.

Maintenance Guide: How to Extend the Life of Your Windshield Film

If one chooses to invest in protection film, treating it correctly is essential to maximize the amortization period of the investment. The film is durable, but it is not invulnerable.

- Wiper Management: This is the single most critical factor. Hardened, dirty rubber blades act like sandpaper. It is advisable to install new wiper blades immediately after filming. Furthermore, keeping the blades clean—wiping them with a damp cloth weekly to remove road grit—can double the lifespan of the film’s top coat.

- Fluid Selection: Avoid washer fluids containing high concentrations of ammonia or harsh acids, as these can chemically degrade the hydrophobic coating over time.

- Ceramic Boost: Applying a dedicated ceramic booster spray designed for vinyl/PPF every few months can replenish the hydrophobicity and reduce surface friction, allowing wipers to glide more smoothly.

Conclusion: The Strategic Value of Preservation

There is a change in the economics of automotive ownership. The smarter the vehicle is, the more vulnerable and expensive to fix it is bound to be. The windshield is no longer a mere wind deflector; it is an important lens to the safety systems that save you.

Thus, the choice to apply protection film is not only the question of not having a broken screen; it is the question of maintaining the factory-level integrity of your vehicle ADAS sensors and not spending time on invasive repairs. Although it might not be a necessity to all cars on the road that qualify as economy cars, in the case of luxury cars, EVs, and off-road systems, it is a logical financial hedge against a high-probability risk.

Nevertheless, the effectiveness of this hedge is fully determined by the quality of the material. The distinction between a frustrating experience and long-term satisfaction, as we have discussed, is in the manufacturing details, namely, the optical clarity of BASF PET and the stability of high-tech nano-coatings. When you purchase a solution that is designed to these industrial standards, like FlexiPPF, you are not only purchasing a film, you are buying a guarantee of peace of mind, that your car will be as clean and functional as it was when it first came out of the showroom.