In assessing the upgrades of the automotive aftermarket, there are not many parts that change in terms of longevity as much as car window tinting. One vehicle owner might experience film that disintegrates into a bubbling, violet nightmare in eighteen months, whereas another vehicle might retain a factory-like look for more than a decade.

The difference is hardly a question of chance. It is a question of chemistry and physics. A common question among car owners concerns the durability of their investment, but the answer depends nearly solely on product quality—specifically the film layers and the adhesive used to glue them to the glass. To know the true duration of window tinting, one has to go beyond the marketing jargon and look at the materials.

The Short Answer: 1 to 10+ Years

To the people who require instantaneous information to make their buying choices or to plan their maintenance, the service life of window tint usually falls into specific categories depending on the type of film employed in its production.

Nevertheless, there is an important difference that should be made in the definition of the term lifespan. When it comes to professional applications on car windows, the end of life is not determined only by the falling of the film off the glass. It is characterized by the breakdown of its optical and physical characteristics. A film has failed when it experiences color shifting (fading or purpling), loses its ability to reject heat (TSER drop), or changes its appearance.

Quick Summary: Window Tint Lifespan by Material

| Tint Material Type | Estimated Lifespan | Primary Failure Mode |

| Dyed Film | 1 – 5 Years | Fading to purple; delamination. |

| Metalized Film | 5 – 10 Years | Oxidation; radio signal interference. |

| Carbon Film | 7 – 10 Years | None (color stable); rare adhesive failure. |

| Ceramic Film | 10 – 20+ Years | None (structurally permanent). |

| Sputter Film | 15+ Years | Physical damage (scratching) only. |

The gap between a one-year product and a twenty-year product is vast. To understand where a specific application falls on this spectrum, we must analyze the material composition that drives longevity.

Material Matters: The Primary Driver of Tint Longevity

The durability of window film is not an abstract concept; it is the result of the manufacturing process. The industry has evolved through several generations of technology, each addressing the limitations of the last. The question “how long does it last?” is functionally equivalent to asking “what is it made of?”

Dyed Window Tint (The Shortest Lifespan)

The lowest level of the market is dyed window tint. It is built on a layer of dye between the adhesive and the protective top coating or impregnated into the polyester itself. Organic dyes are inexpensive to produce, but are chemically unstable when exposed to direct sunlight.

The UV rays of the sun trigger a photochemical reaction which decomposes the dye molecules with time. This disintegration is visualized in the form of a color change—usually making the film purple. This is due to the fact that the yellow and blue primary dyes break down at varying rates and leave behind the red and blue spectrums that are perceived as purple by the human eye.

Moreover, colored films absorb the solar energy instead of reflecting it. This absorption adds more thermal load to the glass and the film itself, speeding up the degradation of the adhesive layer. As a result, the average lifespan of standard dyed films is usually 3 to 5 years before fading or bubbling occurs to a level that requires removal.

Carbon Window Tint (The Stable Middle Ground)

To solve dye instability, carbon film was invented. Instead of using organic pigments that respond to UV light, manufacturers fill the film with micro-particles of carbon.

Carbon is stable and chemically inert. It is not bleached or faded under the sun. Thus, carbon films are usually called color-stable. The carbon tint of high quality will maintain the charcoal black look throughout its life.

Since the carbon particles are more effective in blocking infrared light than dye without absorbing as much heat, the thermal stress on the adhesive is decreased. This structural stability increases the anticipated life span to 7 to 10 years. Carbon film failure is not often the failure of the film itself, but the ultimate failure of the scratch-resistant coating or excessive mechanical wear.

Ceramic and Sputter Films (Lifetime Performance)

Nano-Ceramic and Sputter films are at the top of window film technology. These materials are a radical change in the management of solar energy.

Ceramic films make use of non-conductive ceramic nanoparticles which are incorporated into the layers of the film. These particles are designed to be spectrally selective—they permit high levels of visible light transmission to pass but provide superior heat rejection and UV protection by blocking radiation. Since ceramic is an inorganic substance, it is not subject to fading and oxidation that afflict dyed and metallic films respectively.

The sputter films are produced in a vacuum chamber whereby the ions of metal or ceramics are sputtered (ejected) onto the polyester surface at the atomic level. This creates a film that is very thin but thick and strong.

These films are usually rated 15 to 20 years in terms of longevity which is basically a lifetime of the vehicle. They are colorless, they do not disrupt electronic signals, and as long as the adhesive quality is equivalent to the quality of the film, they do not bubble. This is a one-time install solution to the consumer.

Invisible Killers: Factors That Shorten Tint Life

Although the longevity depends mainly on the material composition, the environmental and maintenance factors can greatly expedite the aging of even the high quality films.

- Climate & UV Index: Geographical position of the vehicle is a significant factor. A car in Phoenix, Arizona, is exposed to high UV indices and ambient temperatures of over 40 o C (104 o F). This produces a thermal cycle in which the glass swells and contracts considerably and strains the adhesive bond. On the other hand, a car in Seattle or London, which has to deal with less UV and moderate temperatures, places less pressure on the film. A 4-year dyed film in a temperate climate can only last 18 months in a desert climate.

- The “Ammonia” Mistake: Improper maintenance is the most frequent reason of premature failure. A lot of domestic glass cleaners have ammonia. The polyester and adhesive layers of window tint are chemically attacked by ammonia. The repetition makes the film brittle and the adhesive bonded along the edges peels off and delaminates.

- Installing Quality: The longevity is also a factor of the original application. The concept of Clean Room is essential. When dust, lint or hair is caught between the glass and the film when installing, it forms a micro-air pocket. Thermal expansion will eventually cause this pocket to widen resulting in the “fingers” or bubbles commonly found on the back windshield. It is not a material failure, but an installation failure that jeopardizes the material.

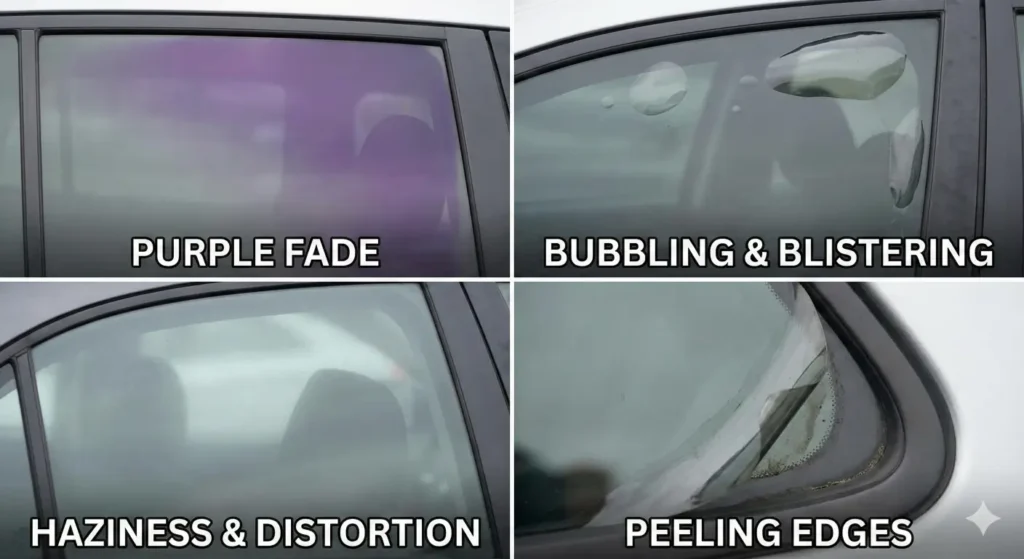

4 Visual Signs It’s Time to Replace Your Tint

The deterioration of window tints is never disastrous; it is gradual. By detecting the initial indications of failure, it is possible to eliminate them before the process is hard. When the adhesive is completely crystallized, the process of removing the old tint is a tedious and expensive one.

- The “Purple” Fade: This is the characteristic of film failure in dye as mentioned earlier. Once the tint stops matching the factory privacy glass, or acquires a violet colour, the UV inhibitors and dyes have been depleted. The movie no longer offers sufficient security.

- Bubbling and Blistering: This is the last phase of adhesive failure. It means that the glue is no longer bonded with the glass and is off-gassing, forming air bubbles. This damage is irreversible. The movie can not be flattened; it should be changed.

- Haziness and distortion: When the window view is hazy, milky, or distorted, then the polyester (PET) layers are distorting or the adhesive is starting to smear. This low angle haze is a serious safety risk and a great hindrance to the visibility of the driver.

- Peeling Edges: Peeling edges are usually due to the friction of the window gasket going up and down, and it means that the adhesive is dry and brittle. When an edge lifts it gathers dirt and debris and can no longer be re-adhesive.

The Economics of Longevity: Cost-Per-Year Analysis

When analyzing the cost of window tint, one must look at the Total Cost of Ownership (TCO) rather than the upfront price. There is a distinct economic argument for choosing high-performance materials like Nano-Ceramic over entry-level dyed films.

Consider a standard ownership period of 10 years:

- Scenario A: Economy Dyed Film ($150 initial cost)

- Lifespan: 3 years.

- Replacements needed: 2 (at years 3 and 6).

- Removal Cost: Old tint removal is labor-intensive, often costing $100-$150 per session.

- Total Cost: $150 (initial) + $150 (replace 1) + $100 (remove 1) + $150 (replace 2) + $100 (remove 2) = $650+, plus the inconvenience of three service appointments and the risk of damaging the rear defroster lines during removal.

- Scenario B: Premium Ceramic Film ($450 initial cost)

- Lifespan: 15+ years.

- Replacements needed: 0.

- Total Cost:$450.

From a purely economic standpoint, the “expensive” film yields a significantly lower cost-per-year. For B2B clients and dealerships, offering higher longevity products protects reputation and increases customer retention, as the product does not deteriorate while the customer still owns the vehicle.

Why Sourcing from a Reliable Manufacturer Guarantees Lifespan

While the category of film (Ceramic, Carbon, Dyed) sets the theoretical lifespan, the manufacturing execution determines the actual reality. Not all “Ceramic” films are created equal. The longevity of the product relies heavily on the quality of two specific components: the PET base and the Adhesive.

At FlexiPPF, we approach window film manufacturing as a precision engineering discipline. Our capability to offer a 10-year warranty on our products is not a marketing calculation; it is a result of our supply chain and production standards.

The Role of High-Grade Adhesives & PET

Ceramic layer is not the most likely point of failure of window film, but the glue. Poor quality adhesives are not thermally tolerant. Surface temperatures may go higher than 60℃ when a car is parked in the sun. Poor adhesives become soft, move, and ultimately burst gases which lead to bubbles.

FlexiPPF employs Ashland Adhesive which is imported directly to the USA. Ashland is the industry leader in high-performance pressure-sensitive adhesives, which have low VOC emissions, superior optical clarity, and high heat resistance. This makes sure that the bond is stable even after years of thermal cycling.

Moreover, we use BASF Polyester Base that is made in Germany. German PET has tensile strength and optical purity that make our films not develop the waviness and distortion that is typical of cheaper substitutes. This mixture enables our films to resist up to 80℃ without deforming its structure.

Lab Testing and Real World: How Durability is Assured

We are not a guesswork manufacturer as an Expert R&D Team and a one-stop manufacturer. We have a 60,000m² facility with German Brunker production lines, which undergoes stringent testing procedures to prove the lifespan claims prior to the product getting to the market.

Our films are put through QUV Accelerated Weathering Testing. We have found that our films still have their color vibrancy and rejection properties after 5000 hours of UV irradiation. This is an imitation of years of severe sun exposure. We also perform double 85 testing (85℃ temperature at 85 humidity) to make sure that the film does not delaminate in tropical conditions.

FlexiPPF has the capability to deliver a product designed to last long; whether you need a particular VLT, a bespoke texture, or a special heavy-duty architectural film, the speed of delivery FlexiPPF can deliver a product (1-2 days to stock) and the customization features (48-hour design turnaround) will guarantee that you get the product you need.

How to Extend the Life of Your Window Tint

Even the highest quality Nano-Ceramic film requires proper care during its initial bonding phase and throughout its life. To maximize the investment:

- Respect the Curing Time: After installation, the moisture between the film and glass must evaporate. Do not roll down the windows for at least 3 to 5 days. In colder climates, this curing process may take up to two weeks. Premature movement can shift the film before the adhesive has set.

- Proper Cleaning: Clean the windows using a soft microfiber cloth and a mild, non-ammonia soap solution (such as baby shampoo and water). Avoid paper towels, which are abrasive and can leave micro-scratches on the scratch-resistant coating over time.

- Check the Gaskets: The rubber seals (gaskets) at the bottom of the window frame can trap grit and sand. As the window rolls down, this grit acts like sandpaper against the tint. keeping these seals clean prevents vertical scratches (streaking) on the film.

For a detailed walkthrough on the application process, please refer to our guide on how to install window tint properly.

Conclusion: Making the Right Investment

The answers to the question of how long does window tint last are determined by the options used during the time of purchase. It is a compromise between initial cost and long term material physics. As much as dyed films can provide a temporary solution, the current Carbon and Nano-Ceramic technologies can provide a permanent upgrade of the vehicle glass.

In the case of retailers, installers, and distributors, the solution to eliminating warranty claims is to find products that are scientifically designed to withstand the elements.

In case you are seeking a supplier of window films that integrates the state-of-the-art German production machinery, high-quality American adhesives, and a 10-year warranty, call FlexiPPF today. Our team is willing to offer samples, quotes and the technical assistance needed to take your product offering to the next level.