A good vinyl wrap will provide a radical change of appearance to the car, as the owners can change the color of the car or place on their own graphics but not as permanent as a new paint job. It is an alluring remedy particularly in a car whose paint has passed its prime. This poses the most critical question to many owners: can a car wrap be used to cover a bad paint in order to conceal the flaws?

Quick fixes are really attractive but in professional wrapping of vehicles, surface integrity is the most important thing. This blog post is a conclusive guide, and it dissects the dangers, diagnosis of paint states, and the proper steps that need to be undertaken to ascertain the perfect and lasting outcome. We shall discuss why the best thing about a successful wrap project is the condition of the paint of your car.

The Quick Answer: A Risk Professionals Advise Against

To put it plainly: it is physically able to apply the vinyl on a damaged paint surface, but it will not be suggested by a reputable professional. Most of the knowledgeable installers and wrap guys agree that doing so is a big risk that makes vehicle wraps fail the 3 main pillars of having good aesthetics, length of life, and the integrity of the underlying surface. It is not a solution to hide the problems such as a peeling clear coat or deep scratches, and it is very expensive deferral of the failure that is sure to come.

Not only will the vinyl car wrap not cover most of the visible imperfections, but it will also not adhere well, which will completely reduce the lifespan to a minimum. More importantly, it is possible that the process with its removal can drag loose flakes of paint, leaving the original car paint in a considerably worse condition than it was previously. It is a bet that is going to backfire.

How a Vinyl Wrap Magnifies Imperfect Paint

Among the most widespread myths is the idea that a layer of the vinyl will become a kind of a thick blanket softening and covering the imperfections on the surface. The fact is just the contrary. Imagine a high-gloss wrap: it is a finished wrap that is thin and is placed smoothly over all the contours of a car and is exactly where it is needed. It is made to be incredibly conforming, or in other words, it will also sink in all the scratches, dips and grooves in the surface below it.

The material will telegraph any imperfection on the surface. The pile of the rock chips is going to be a field of small bumps. Deep marks will be seen in form of channels on top of the film. The wrap can even see through the paint jobs which have a subtle orange peel texture. These flaws are not shrouded in the vinyl; they are carefully traced. Rather than a smooth, liquid look, the outcome is a textured, rough look that sends instant messages of a low-quality work and an unprepared surface, and is, in fact, a waste of the wrap.

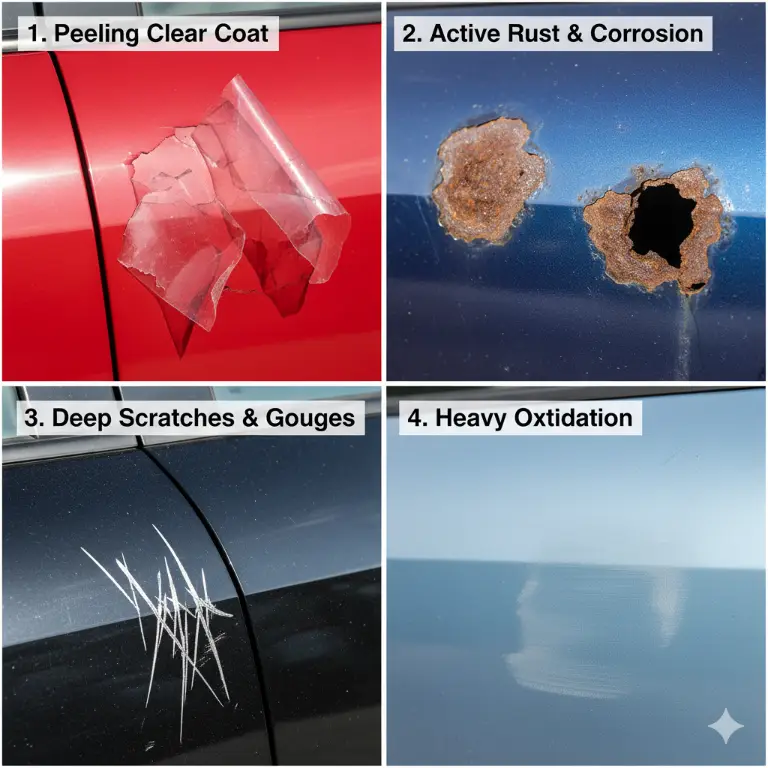

Red Flags: Paint Conditions That Guarantee a Bad Wrap

The substrate needs to be clean, smooth and stable to be a professional outcome. Some paint situations give rise to an insurmountable and uncompromising obstacle to the successful installation. When your car has the following then a wrap should not be considered until the troubles have been fixed by someone who has expertise.

Peeling Clear Coat / Paint

This is the most prevalent and essential deal-breaker. Once the top coated clear layer or the colored layer starts to flake and peel, it is an indication of a basic adhesion failure. The adhesive on the wrap will be stuck on these unstable, peeling paints, not the fixed body of the car. Any stress forced on the vinyl in the course of installation, or just by the natural expansion and contraction, will raise the flakes along with the wrap attached to it. Removal will ensure that severe damage is created and this will result into a larger area of damage.

Active Rust or Corrosion

Rust is a car cancer and a vinyl wrap on the rust is like applying a bandage on the tumor. The wrap will also lock away the moisture to the panel, and this may speed up the corrosion process behind the scenes. Moreover, the rust particles form a rough porous surface that gives a terrible surface on which the adhesive can bond on, resulting in bubbling and lifting. The wrap will not work and the issue behind it will have been escalated much.

Deep Scratches and Gouges

There is a need to distinguish between surface swirls and actual damage. The scuffs of light which have not broken through the clear coat may be polished off. Nevertheless, gouges or deep scratches that may have reached the primer or the bare metal are too serious to be covered. These channels will cause the vinyl to sink making it very visible. These spots also depict a violation of protective layers of the paint, exposing the metal to the moisture as well as corrosion beneath the wrap.

Heavy Oxidation

Painting that has been seriously impaired by the UV rays will assume a dry and flat look. This is oxidation, or the breaking down of the binders of the paint, forming a rough and slightly powdery surface. An oxidized finish is not stable, though in some cases, the slightest amount of oxidation can be removed through polishing. The surface is also not as solid and smooth as the adhesive on a wrap demands to be in order to achieve a strong and durable connection, and thus the failure occurs early on, particularly at the edges and seams.

Is Your Car’s Paint “Good Enough” for a Wrap?

Not all paint defects are total barriers to entry. It is a gray zone that a finish of a vehicle is not ideal but it might be ready to be wrapped. Professional evaluation and painstaking preparation are critical here. In case your car paint is in a fairly good condition but has isolated problems that are small, there can be a way out.

Take into account such problems as light surface scratches, small stone chips that have not resulted into peeling, or paint that has faded but is still soft to the touch. The professional job in such instances may be taken up by a skilled technician performing surface preparation steps. This may involve:

- Wet Sanding: This is done cautiously by sanding the surface, ensuring that all minor flaws are removed to produce a smooth canvas.

- Polishing: Light scratches are erased using the compounds to refine the surface to a smooth and shiny surface to hang onto the vinyl.

- Filling and Spot Priming: In the case of small, stable rock chips, a technician can fill the chip, sand it flat, and then put a small portion of primer in order to close it before wrapping. This does not allow the chip to appear as a divot.

The task is always the same to provide a surface that is as near as possible to a perfect factory-finish, good paint job. This is a tedious preparation that needs competence, yet can turn a car that would have been unwrappable into a possibility.

The Foundation for a Flawless, Long-Lasting Wrap

Finally, two absolutely indispensable components of a beautiful and resistant wrap are a well-prepared surface and a high-quality professional film. It will be an insult to the effort and investment you have made once you have taken the time to ensure you have built an ideal base by fixing your paint on your vehicle to compromise on the quality of the material. This is where the difference between amateur performance and professionalism is exposed.

Professionals and expensive auto stores put their reputation on the line with each job, hence their collaboration with high-quality material suppliers. FlexiPPF is one of the major manufacturers and suppliers of high-performance paint protection films and wrap vinyl, which is why its developers create materials with the highest level of durability, adhesion, and an unblemished finish. We have our films which can be accessed by the certified trade professionals Flexippf and possess sophisticated adhesive technologies and remarkable conformability that works best when placed on a well-prepared surface. The use of a film of professional quality on a substandard base is one of the main causes of inappropriate failure of installation. Not only does it cost you an investment, but it also kills the potential of the film as well as it casts a bad light on the work of the installer.

To auto styling companies and wrap installers who need a quality materials supplier that has committed itself in providing quality products, we encourage you to consider our product lines. If you want to partner with us, you can use our contact form on the internet to make sure that your work is established on the values of excellence.

Smart Alternatives if Your Paint Isn’t Ready

In case you realize by carefully assessing your paint that it is inappropriate to wrap, this does not mean that you should be bored. Some of these solutions are viable and solve the problem at its core which would give a firm base to a wrap in future or a beautiful finishing itself.

Professional Paint Correction and Repair

In case of localized damage on the vehicle e.g. a peeling panel or deep scratches on one door, then specific repair is the most effective solution. Only the affected areas can be sanded, primed and repainted by a reputable body shop. This can be quite less expensive than a complete repaint and recovers the required surface integrity of a wrap.

Full Repaint

In case the damage is extensive, e.g. systemic failure on the clear coat on the roof, hood and trunk, a replacement paint job is the best option. Although it is the largest investment, it is the only one that will help to restore the finish on the vehicle. It has a flawless, clean surface which is best suited to a vinyl wrap, though one should remember the excess paint will require time to outgas (usually 30-90 days), so the excess paint should be given time to cure properly before any film is applied.

Liquid Wraps / Plasti Dip

More lenient of any small paint flaws than traditional vinyl, liquid wraps in the DIY sphere or something a bit cheaper can be more accommodating to small paint blemishes. These sprayable finishes are more dense and have the ability of filling up small scratches better. Nevertheless, they are not as glossy, well-finished, or long-lasting as a professional wrap which is done in vinyl.

Final Verdict: Your Action Plan Before Wrapping

It is possible to simplify the process of deciding whether to wrap a car with less-than-perfect paint by going through a logical step-by-step process. This course of action will enable you to make a well-informed choice and save your investment.

Step 1: Assess Your Paint Condition

Objectively examine your entire vehicle in good light. Look for the major red flags discussed earlier: peeling, rust, deep scratches, and heavy oxidation. Be honest about the condition. If you can feel an imperfection with your fingernail, it will almost certainly show through a wrap.

Step 2: Get a Professional Opinion

Visit at least two well known wrap installers to have a face to face consultation. They are experienced people who know how to spot borderline problems and can answer you categorically whether your paint is a worthy candidate of wrapping or it needs repair work done first.

Step 3: Repair Before You Wrap

In case a professional suggests that paint should be repaired, listen to him. Do not attempt to engage an installer who will cut corners. The long term plan is to invest in doing a proper bodywork or even a new paint job and the only thing that can guarantee an effective outcome of your wrap.

Step 4: Choose a Quality Film for a Lasting Finish

After making sure that your car has a clean surface, you need to pick a good quality of wrap film of a good manufacturer. An elegant material will not only appear better but also will be stronger and will not fail so easily, securing your car and your investment in a few years.